Datum Electronics (Chile) - Datum Electronics were asked by B-Konnet, to provide an alternative to physically checking silo stock levels in South America and we recommended the Series 460 Bolt-On Strain Gauge, as a solution.

Based in Santiago, B-Konnet provides cutting-edge inventory solutions for raw material processing in South America and developed a system called B-silo, which is able to continuously monitor the level of liquids, powder and solids for a wide range of industries. Their product can detect weight changes in a silo (or multiple silos, that need to be monitored at a facility) and instantly provide this information through a local network or via the Internet.

With a simple set up, B-silo can also email alerts for order levels, as well as set alarms for low or high stock level in silos, making logistics and stock decisions easier. It can also display historical graphs and trends, making forecasting a much simpler task.

One of B-Konnet’s clients is a raw material manufacturer that employed staff to climb silos to visually assess stock levels in silos and hoppers. The height of the silos, dirty environment and frequent rainfalls in Chile, made the job inefficient and extremely treacherous, so they were looking for a suitable automated alternative.

Alternative mechanical solutions, such as load cells, were ruled out as they required structural intervention to the silo, which would require the plant to stop, allowing fitment and due to the region being susceptible to earthquakes, this could lead to significant downtime and risk.

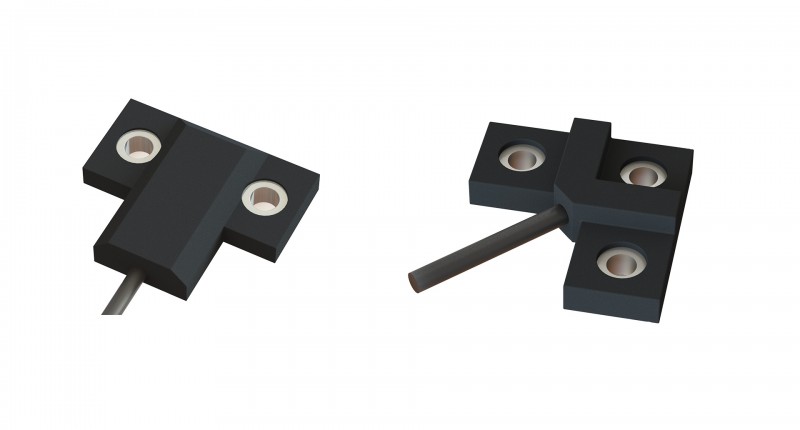

Bolt-On Strain Gauge Sensor Solution:

As Datum’s bolt-on strain gauge sensors are attached directly to the supporting structure, they do not require any structural intervention and, therefore, do not affect the design and operation of the plant.

Secondly, bolt-on strain gauge sensors offer high accuracy, a stable measurement and are very simple and easy to install. They have no moving parts and are maintenance free. The sensors measure changes in stress in the structure and provide an output in proportion to the weight of the material.

In addition, their performance is not affected by material or process conditions. They provide continuous level measurement regardless of dust, content or an angle of repose of raw materials, even during filling. Equally important, Datum Electronics’ 3-Hole Bolt-on strain gauge sensors can compensate for temperature differences between the structure and the sensor, making them an ideal choice for continuous silo level measurement of bulk solids handling and processing, in both harsh and challenging conditions.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.