It‘s all about the accuracy of the measurements, and that accuracy needs to be present from the moment the product enters the packaging process. Successful vegetable packagers are aware of this, which is why they know that they have to use the best equipment if they want to stay successful. In fact, one of the biggest of these companies in Europe has made it one of their aims to always exploit the latest cutting-edge technologies in order to keep themselves one step ahead of the competition.

This company is one of the largest producers of canned and frozen vegetables in Europe, and is located not far from the seaport of Gdansk, Poland, in a rich agricultural area renowned for the quality of its fruits and vegetables. Is there a better place to build a vegetable production plant? Not only does this location make it easier for contractors to deliver their vegetables from a cultivation area that is over 4,000 hectares large, but it also allows the company to be involved in all aspects of the lifecycle of the vegetable, from the preparation of the ground by way of fertilizer, to the laboratory analysis of the final harvested sample. All of this effort, of course, ensures that the product shipped to the customer is of the highest possible quality.

The common beans are unloaded from the delivery trucks onto a wide conveyor belt that carries them into the factory.

Keeping up to date with current technologies:

A few years ago, this company decided that it was time to improve the part of the production line where the common beans were unloaded from the delivery trucks and conveyed into the building. They contacted 4SELF Łukasz Kosiorek, a local engineering company with a background in measurement and control systems, and a dialogue was started.

First, it was decided that the weighing of the common beans had to be accurate to within 1%. Secondly, the new weighing equipment had to be versatile enough to fit into the existing production area within the existing facility. Renovations of any kind, either to retrofit the existing plant, or to build a new one, would have been prohibitively expensive.

So, how could 4SELF meet these requirements, and keep a company that‘s been around since the 1930s current? Why, by getting Siemens involved, that‘s how.

Brand new solutions for age-old challenges:

4SELF analyzed the system, identified the following challenges, and proposed the accompanying Siemens solutions:

- Limited conveyor height didn‘t leave much room for a belt scale - Because of the existing architecture, a compact belt scale was needed, so the engineers turned to the MILLTRONICS MCS belt scale that would not only fit the space required, but also boasted high precision stainless steel load cells.

- Short distance between the belt scale and the head pulley - Because of the way in which the existing factory was set up, there was only one idler between the belt scale and head pulley. This is not an ideal situation, as there are a number of stressors on the conveyor belt as it changes profile from a troughed idler to a flat pulley, and these stressors can cause enough disruption as to affect the belt scale measurements. In this case though, the technicians could use electronics to adjust the output to account for it.

- Unknown diameter of the tail pulley made it difficult to calculate the speed sensor pulse constant - The 4SELF engineers wanted to use a SITRANS WS300 speed sensor to measure the belt speed, but there was a problem: most of the belt scale weighing modules can only calculate the speed by knowing the exact diameter of the pulley to which the WS300 is attached - a parameter that wasn‘t available and difficult to measure.

The vegetable processing company saw, that this solution aligns with their aim to increase production efficiency by using new technologies, so they approved it.

The benefits of a modern weighing system:

In the new conveyor system that the 4SELF engineers installed in the plant in Poland, the freshly harvested beans are now unloaded from the delivery truck by way of a broad conveyor belt that is 2900 mm (114“) wide. The speed of this short conveyor is controlled by a PLC, and set between 0.015-0.12 m/min (5 and 15 t/h).

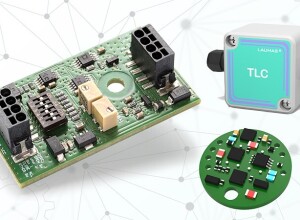

SIWAREX WP241 weighing module:

- Easy integration in SIMATIC S7-1200 but also can be operated without SIMATIC CPU

- Designed for monitoring belt scale and weigh belt applications

- Standard functions such as flow rate, belt speed and belt loading can be adapted and extended as required

- Low- to high-resolution shaft-driven speed sensor

- Operates in conjunction with a conveyor belt scale, providing a signal to an integrator which computes the rate of material being conveyed

- One of the lightest and most durable units ever developed for monitoring conveyor belt speed

- Suitable for outdoor installation

- Compact, rugged, modular, heavy-duty belt scale for use in mobile crushers and aggregate screening plants

- Continuous, in-line weighing at minimal cost

- The stainless steel load cells

- Modular construction and easy assembly of the MCS

The beans then fall from this bigger conveyor onto a second belt that is 800 mm (31.5“) wide. Once on this belt, they are weighed by the MILLTRONICS MCS as it moves along at a speed of about 0.5 m/s (or 30 m/min), a speed that is measured by the SITRANS WS300 speed sensor. Both the belt scale and the speed sensor communicate with the SIWAREX WP241, which is directly connected to a SIMATIC S7-1200 PLC.

It‘s difficult to say who benefits most from this new weighing system. Definitely the vegetable packaging company is happy. Not only weighing its healthy beans within the required 1% accuracy, but - by using the SIWAREX WP241 - it has also met its objective to use the latest cutting edge technology.

It could be argued though that the biggest winner here is you - the consumer. Next time you go to the grocery store to buy your vegetables, you will know that the product that you‘re buying was packaged efficiently and accurately, meaning that you are getting exactly the amount of good quality vegetables as promised.

Wait until you tell your doctor exactly how many vegetables you‘re eating!

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.