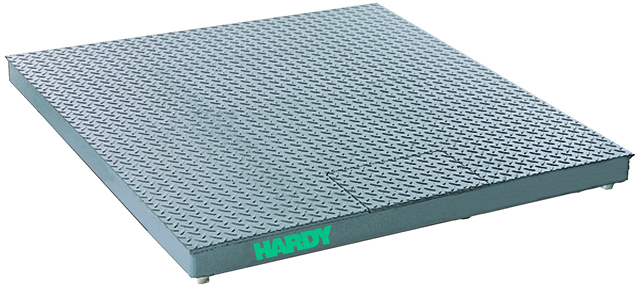

“Hardy Floor Scales are designed and built for harsh chemical and wash down industrial environments, yet are easy to use and install with the latest advancements in weighing technology”, they added.

"Hardy Floor Scales come with Hardy’s core features: weightless calibration (C2®) and operator diagnostics (Integrated Technician®). The key value of this product line is its ability to pair with any of Hardy’s instruments or PLC weight modules to get the benefits of Hardy Process Toolbox features. Hardy’s C2 enables fast, accurate electronic calibration without test weights. The C2 system reduces downtime for installation or repairs and eliminates test weight related injuries. This is crucial when scales are used in hazardous areas. Hardy also provides diagnostic and troubleshooting tools that read individual weights and voltages to help users in isolating problems and ensure the long-term integrity of an industrial scale solution", explained Hardy.

“Best-in-Class Durability”:

Hardy Floor Scales are rated for 250,000 – 300,000 loading cycles under normal loading conditions. Available in eight sizes from 30 x 30 inch to 72 x 96 inches in 1, 2.5, 5, and 10 thousand pound capacities, each scale includes stainless steel IP69K load cells and a built in Hardy HI 6011 Summing Card in a NEMA 4 enclosure. All weight capacities come in stainless steel or painted carbon steel with smooth or tread deck. Each scale is complemented with a full range of accessories. Hardy also offers custom sizes for non-standard applications.

Hardy Floor Scales are offered with a full complement of accessories: 48-inch indicator column for mounting a Hardy weight processor or controller, portability kits, pit frames, fully length ramps, bumper guards with available mitered corners, and bolt-down plates.

List of Certifications:

- UL, CUL, CE, RoHS and REACH Compliant

- Hazardous Areas*:

- Class I, Division 1, Groups A, B, C, D, T4; Zone 0, Group IIC, T4; Division 2, Groups A, B, C, D, T5

- Class II, Division 1, Groups E, F, G, T4; Zone 20, Group IIIC; Division 2, Groups F, G, T5

- Class III, Division 1, T4; Division 2, T5

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.