- False connection of the 4 - 6 wires between the load cells and the junction box

- The Load Cells are out of balance

- Cable break or bad connection at the terminals

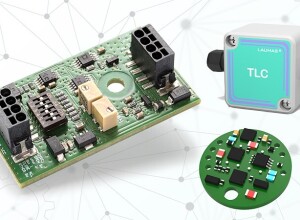

To solve this problem in the future, Hense Wägetechnik developed a “smart“ solution called the “intelligent junction box”.

The intelligent junction box is powered via the load cell amplifier and does not require a separate supply voltage. For this reason the intelligent junction box can be used in place of a standard junction box. The following parameter are continuously monitored and display:

- Over- and underload of load cell signals (adjustable)

- Cable break and contact faults

- Excitation voltage to load cells

- Load deviation on load cells

The Display shows the actual conditions of the weighing system:

The load cell signal can be transferred via conventional 4 or 6 wire connection to the amplifier. Alternative a save 2-wire CAN bus connection can be used for a distance of 200m and more. If more than 4 load cells or one silo should be monitored, the CAN bus allows to establish a 2 - wire network.

To complete the system, Hense Wägetechnik GmbH offers a high precision load cell amplifier, which is able to communicate with the “intelligent“ junction box.

The load cell Amplifier „Target 260” receives the CAN bus information and shows the weight and fault information in the bright display. Errors are stored in the memory of the intelligent junction box and the “Target 260” electronic.

This diagnostic function helps to isolate the source of the error with a short time period. The “Target 260” amplifier can be supplied for wall or table, panel or DIN - rail mounting. A stainless steel enclosure is available as an option.

The following output signals are available: 0(4) - 20mA / 0 - 10V / 0 - 5V / 3 voltage free relay contacts / USB interface or serial interface RS 232.

Optional interface: Profibus DP and Profinet.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.