Intercomp Company (United States) - Clarks Ag Supply, an innovator in the design of seed tender systems since 2000, was searching for a better option for installing on-board weighing systems on Easiload seed tenders. The system they were previously using increased the height and weight of the Easiload system, and its complex design could take an entire day for customers to retrofit into their Easiload seed tender after purchase.

Clarks Ag Supply listens to its customers and, through the past 22 years, has gone through an evolution of what works and what doesn’t. It was critical to find a better on-board weighing option which was easier to install and would not increase the height of the seed tender. Intercomp designed that solution.

The original scale system Clarks had been using required an existing seed tender to be heavily disassembled before it could be installed, requiring the fabrication of multiple parts and hours of labor. It was difficult to field install if purchased by a Clarks dealer/customer after the tender sale and wasn’t much easier to install in the Clarks factory before the sale. It also used a large subframe with multiple custom mounts and hex bolts to hold the load cells in place, which increased the height and weight of the Easiload system, a significant drawback when the low-profile was a major selling point.

After examining the equipment, Intercomp’s engineering team had an inventive idea: they would develop a scale system which could replace the spacer in the existing mounting bracket of the Easiload seed tenders. Originally, the solution included a round bar hitch load cell which still required a small amount of fabrication, however, it was revised over the years and eventually replaced with a ladder hitch load cell which made it simpler to adjust the hitch height and decreased install time even further. Through these design improvements, Clarks could save hours of manufacturing time when customers added a scale package to their order. Additionally, they could offer their previous Easiload customers a scale system that was a drop-in replacement for the mounting brackets on their machine with no fabrication required.

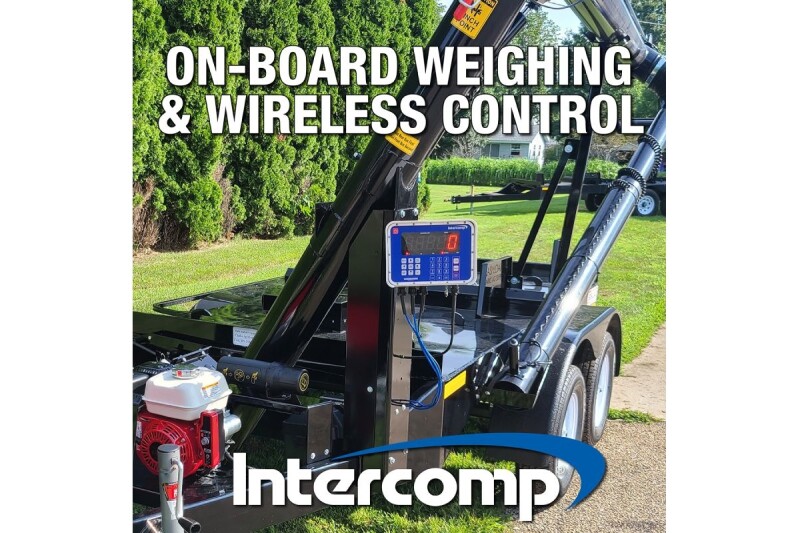

Hours of time saved is not the only benefit Clarks and their customers experienced with the switch to an Intercomp On-Board Scale System. Included in the package is an Intercomp 720 Series indicator that streamlines the installation of auto-dispense, a function which increases operational efficiency by ensuring accurate weights of each load. Furthermore, the 720 Series indicators have a bright 1.5" (35.1mm) LED screen which provides clear visibility in all lighting conditions, an important feature when operations are sometimes running 24 hours a day.

Intercomp’s design decreased the time required to install the scale system by 50% while maintaining the low profile of Clarks Easiload seed tender. Clarks’ customers realized the additional benefits of a highly accurate auto-dispense feature as well as an enhanced indicator view when Clarks upgraded to an Intercomp On-Board Scale System.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.