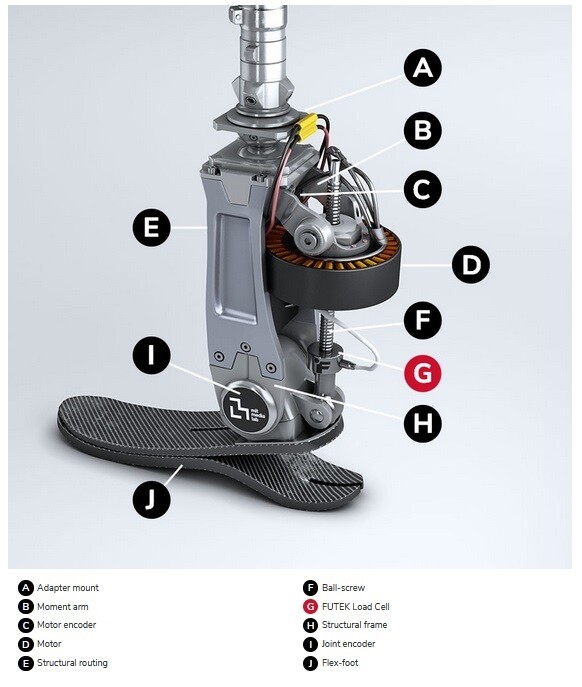

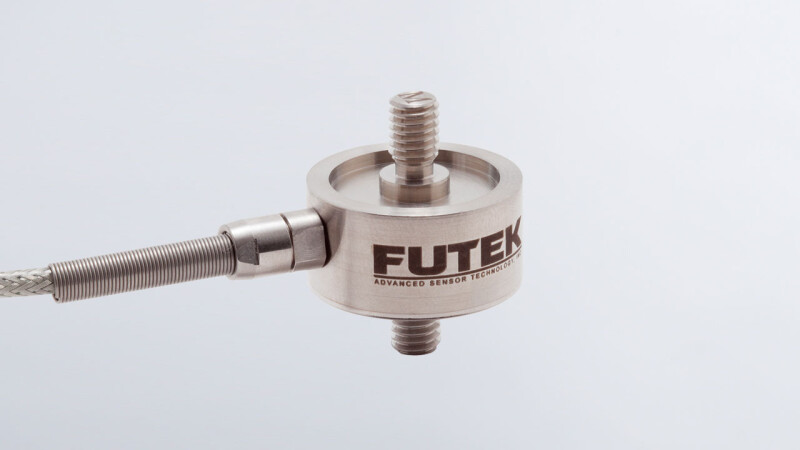

FUTEK Advanced Sensor Technology, Inc. (United States) - Elevate Biomechatronics with the MIT Media Lab! Introducing TF8, a groundbreaking prosthetic actuator powered by FUTEK's LCM300 load cell. Seamless integration, bi-directional communication, and a relocation technique redefine the human-machine interface. FUTEK proudly contributes to this life-changing biomechatronic achievement.

Best foot forward:

This robotic prosthesis from MIT’s Media Lab allows amputees to feel like they have a biological leg.

For Matthew Carney of MIT Media Lab’s Biomechatronics group, the goal of building hyper-sophisticated machines is decidedly human. “At the most fundamental level we are trying to eliminate disability. We want to develop technologies that allow there to be no difference between disabled people, and someone of a normative body type,” says the biomechatronic engineer. He has designed a device that comes very close to doing that. Carney’s PhD work for MIT is the revolutionary TF8 actuator, an untethered, lower-extremity powered-prostheses designed to replicate biological kinetic and kinematic function of ankles. The project has its origin in the powered prosthesis work pioneered by Dr. Hugh Herr and the team at the MIT Media Lab Biomechatronics Group (check out the video below to see how one of the engineers in that group has personalized the actuator for his own use).

This next-generation biomechatronic solution — which uses FUTEK’s LCM300 load cell for its force measurement — is built with a tightly integrating neurally-controlled power-dense actuator that allows it to be a nearly seamless replacement for a human limb. The device replicates natural human movement by combining walking data and optimized mechanical and electrical systems. But what really makes it novel is that it facilitates bi-directional communication between the body and the robot. This means that the amputated user experiences an artificial lower leg that not only functions, but also feels like a real one, as they can sense the robot’s movements and what it will do next. This interaction between human and machine is achieved through a new MIT-developed amputation technique that relocates the muscles above the amputation zone instead of cutting them off, allowing the brain, body and bionic device to interface in a way that is entirely unprecedented. FUTEK is humbled to contribute to this truly life-changing achievement.

“Robotic prostheses integrate biomechanics, mechanical, electrical, and software engineering, and no piece is off-the-shelf. To attempt to fit within the confines of the human form, and to match the bandwidth and power density of the human body, we must push the bounds of every discipline: computation, strength of materials, magnetic energy densities, sensors, biological interfaces, and so much more.” Matthew Carney, Postdoctoral Associate, MIT Media Lab Biomechatronics Group.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.