Dillon Force Measurement (United States) - Minnesota Elevator, Inc. (MEI), based in Mankato, Minnesota, has nearly four decades of experience in designing, manufacturing and servicing elevators for both commercial and industrial installations. The company specializes in custom elevator designs/manufacturing, as well as maintenance and modernizations for a variety of customers including property management companies, schools, hospitals and other institutions to support infrastructure expansions, meet new building codes or to help them solve any of their vertical transportation needs.

In addition to these projects, the company maintains and services numerous traction elevators annually to ensure each operates properly and wire rope tension is well balanced. This process used to be an arduous task for elevator service technicians.

“Each elevator car is suspended by anywhere from three to 10 wire ropes, and each wire rope must bear an equal load,” said Ron Romnes, Vice-President of Field Operations at MEI. “If one wire rope is doing more work than the others, it causes irregular wear, as well as a more inconsistent ride for customers.”

To test wire rope tension using standard equipment, it would take a service technician approximately one hour to tension the wire ropes with a spring-type scale, requiring a “trial-and-error” process to ensure each was tensioned equally. For elevator modifications, the process became more complex, as MEI personnel needed to weigh the elevator car before and after modifications took place to ensure the elevator still bore a suitable load-defined as no more than a 5 percent increase in gross load.

“In these instances, our crews would need to shut the elevator down and hoist the car onto a crane scale to determine the weight of the elevator,” Romnes said. “This was a time-consuming process, taking more than two hours, excluding travel time. Upon completion of the elevator modifications, the entire process would have to be repeated. It was an inconvenience to our customers as well as a substantial labor cost for us.”

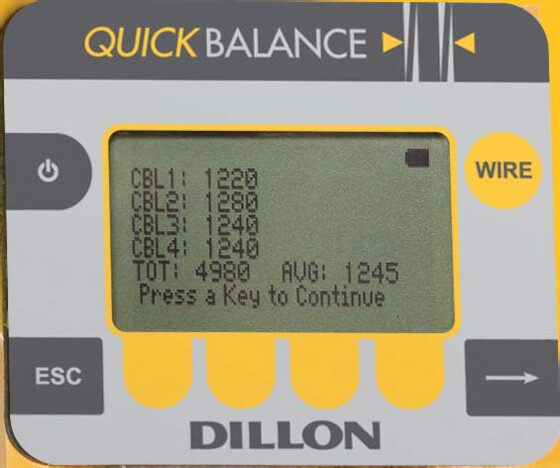

To expedite the process of gathering individual wire rope tension data and overall elevator weight, MEI selected the Quick Balance Tension Meter by Dillon Force Measurement. Quick Balance safely and efficiently measures wire rope tension and compares it to target settings for each wire rope stored within the device’s memory. It also totalizes the collected measurements to yield the full elevator weight.

“The Quick Balance Tension Meter clamps onto each individual wire rope and determines the force rating, or wire rope tension,” said Wayne Wille, area sales manager for Dillon. “Quick Balance only requires one person to operate, and it can be attached, measure the force rating and be detached in seconds.”

During this process, Quick Balance collects and displays the force ratings for each wire rope, allowing the service technician to quickly compare tension readings and determine which require adjustment. With the device’s totalizer, a single technician can check wire rope tension and determine overall elevator weight in minutes, all without requiring manual documentation or conversion charts.

Along with these savings, Romnes said MEI has been able to optimize their customer visits by integrating wire rope checks into tasks such as surveying.

“When we modernize an elevator, we send a salesperson to survey the elevator shaft and note its measurements, as well as any other factors we’ll need to account for during the modernization process,” Romnes said. “Our salesperson can easily use the Quick Balance to not only gather overall elevator weight but also get a measurement of the counterweights. By taking a few extra minutes during the initial visit, we are able to minimize elevator downtime for our customers and maximize field time for our sales and service teams.”

Once the modifications are made, a single technician can measure both the elevator and its counterweights, to verify that both are in the correct ratio with one another-and therefore ensure proper operation.

“Quick Balance has resulted in a substantial time and cost savings for us,” Romnes said. “What used to be a two-and-a-half hour operation for two of our technicians now takes one person less than five minutes.”

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.