Varpe Control de Peso, S.A. (Spain) - As global production lines evolve to demand higher speeds, stricter compliance and tighter quality control, VARPE’s dynamic checkweighers stand out as a strategic asset for manufacturers.

1. Market Context & Strategic Value:

In food, beverage, chemical and pharmaceutical manufacturing, the need to weigh 100 % of packaged goods without interrupting the production line has become non-negotiable. Non-compliance can lead to risk, wastage, rework and reputational damage. By deploying robust automatic weighing instruments (AWIs), manufacturers not only safeguard compliance (e.g., EU MID for pre-packaged goods) but also unlock operational efficiencies: fewer rejects, accurate average weight control, integrated inspection and actionable data analytics.

VARPE’s checkweighers align directly with these business and operational imperatives — offering manufacturers a way to embed weight-control, traceability and smart data capture into their production ecosystems.

2. Product Range & Configuration Flexibility:

VARPE showcases a broad portfolio of automated checkweighers, designed to address differing production speeds, formats, weight ranges and inspection requirements. Key models include:

-

V2000 STATIC – precision and accuracy for applications that require product stability control.

-

V2000 WAFER – dedicated dynamic checkweigher tailored for wafer production formats (thin, delicate products) on high-speed lines.

-

V2000 ROTARY – meets the demands of specific markets such as aerosols.

-

COMBO RX – dynamic checkweigher integrated with X-ray inspection.

-

COMBI DM – dynamic checkweigher with metal detection included.

-

V2000 CAN - is the ultimate solution for high speed requirements in extremely aggressive environments.

-

V2000 ROBUST – is ideal for bulky and / or heavy products, which require an extremely strong, precise equipment.

-

V2000 ESSENTIA – has the essential functionalities to help control the quality of production thanks to the automatic weighing of 100% of the products without stopping the production line.

-

V2000 CLASSIC – helps you control the quality and profitability of your production thanks to advanced weighing electronics, maximum accuracy and state-of-the-art software.

This breadth enables manufacturers to select solutions optimized to their line speed (units/min), weight range (g) and configuration (single vs multi-lane) while allowing integration of added functionalities (metal detection, X-ray) as needed.

3. Key Technical Features:

Customised solutions for bespoke requirements

Recognising that no two production lines are identical, VARPE emphasises tailored solutions — whether multi-lane conveyors, integrated inspection modules, or bespoke layout adaptations.

Automatic 100 % weight check without interrupting production

VARPE’s AWIs are designed to monitor every unit travelling on the conveyor and execute automatic processes compliant with MID requirements.

Prevent the equipment from having spaces where dirt can be stored. To facilitate the cleaning og machinery. Facilitate inspection and maintenance of equipment.

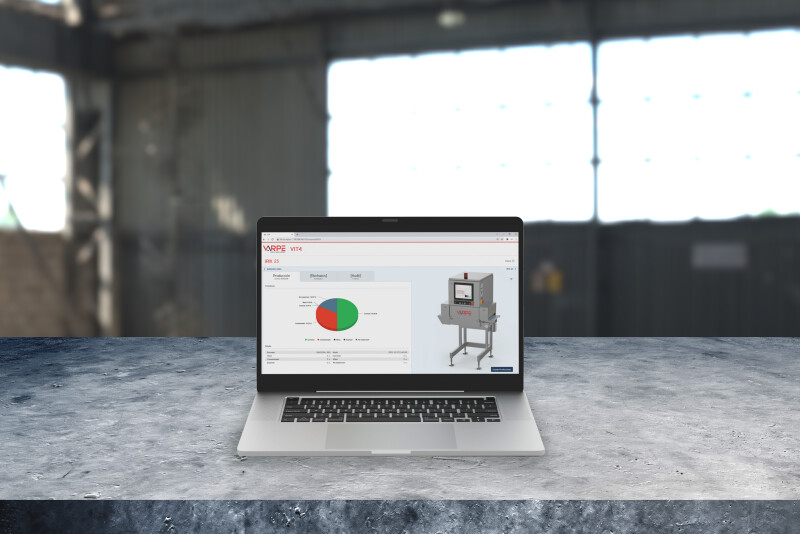

Advanced industrial software & IIoT readiness

VIT4 is a software designed to store, manage and analyse the data created by VARPE equipment during the production process, aiming to Industry 4.0.

4. Commercial Benefits & Business Case:

From a procurement and operational leadership perspective, investing in VARPE’s checkweighers offers multiple commercial advantages:

-

Reduced product give-away and over-weighting: Accurate 100 % checkweighing enables tighter control of target weights, minimising over-filling while staying within regulatory tolerances.

-

Regulatory compliance assurance: With MID-compliant functionality and automatic reject of out‐of-tolerance units, risk of non‐compliance (and associated fines or recalls) is mitigated.

-

Lower total cost of ownership (TCO): Hygienic design cuts cleaning / maintenance downtime; intuitive software accelerates operator onboarding; modular configurations reduce future CapEx for upgrades.

-

Improved line efficiency and uptime: Continuous monitoring and remote diagnostics enable quicker fault resolution, predictive maintenance and fewer line stoppages.

-

Data-driven decision-making: Access to production metrics, weight distributions and historical logs empowers quality teams to refine packaging processes, reduce variability and drive continuous improvement.

5. Typical Applications & Industry Use-Cases:

-

Food & Beverage: For pre-packaged goods (e.g., snack bags, ready meals, frozen products), where weight compliance, hygiene and line speed are critical.

-

Agriculture, Livestock & Fishing: Bulk pack formats and portioned packaging benefit from high-speed dynamic weighing.

-

Chemical & Pharmaceutical: Accurate dosing and product traceability demands suit VARPE’s hygienic, compliant checkweighing solutions.

-

Non-Food Industries: From industrial parts to consumer goods, any application requiring continuous weight verification can leverage these systems.

6. Why Partner with VARPE?

-

Built around ISO 9001 and ISO 14001 certified processes.

-

Strong track record in delivering customised solutions globally.

-

Commitment to R&D and integration of inspection, software and connectivity modules.

-

Full service offering including calibration, after-sales support and lifecycle maintenance.

Conclusion

In summary, VARPE’s industrial checkweighers offer a compelling mix of precision, automation, hygiene and data connectivity to support manufacturers across food, pharma, chemical and non-food sectors. For procurement and engineering decision-makers, these systems represent a strategic investment in quality, compliance and operational efficiency.

Leveraging the flexibility, data readiness and turnkey nature of VARPE’s solutions positions producers to adapt to evolving market demands, regulation and productivity targets.

For further details or to arrange a technical consultation, please visit VARPE’s checkweigher product page or reach out directly to their sales/support team.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.