Stevens Traceability Systems (United Kingdom) - The Important Final Steps.

As any manufacturer knows, packaging can be just as important as the products they contain. When shipping or despatching products, you want to ensure it’s done correctly and efficiently, otherwise, you risk a loss of time, money, and trust. It’s imperative that the packaging contains the necessary information on ingredients and expiry dates for example, for the purposes of traceability. Further to this, a product’s packaging is intended to protect the contents during the shipping process. It needs to be strong enough to be relied on, and its quantity needs to be monitored to avoid running out and facing a packaging disaster. If you’re looking to gain control and manage your packing process, you can do so with our Stevens Packaging software module.

With the Stevens Packaging module, you gain full control over your packing process, allowing you to improve the efficiency of your final processes while accounting for traceability. As a modular component of our wider Dynamic Traceability System, Stevens Packaging can be added to an existing system of ours as and whenever needed by you. If you package your products in outer packaging or do so in bulk for larger sales orders – then our packaging software is the ideal solution. With it, you can keep track of packaging inventory, save time on scheduling recipes and completed products, and make changes on the fly when flexibility is needed.

Why Should You Use Stevens Packaging Software?

Schedule Your Entire Process:

There’s no longer any need to spend hours manually scheduling your production line across every stage of your business operations. You can schedule all stages of a batches production process simply by choosing your final requirement. That’s right, by scheduling your final product, the Stevens Packaging Module will also automatically schedule all the relevant steps across all stages of production from recipe makeup through to packaging and final sales orders. This will not only save you massive amounts of time, but it will also help improve productivity in your operations and provide full traceability throughout.

Automatic Calculation of Requirements:

Relying on manual calculations in production is also running the risk of setbacks caused by errors, especially when your business needs to fulfill a high volume of orders. On a busy factory floor, for example, it’s inevitable that some level of human error will occur. By the packaging stage, these types of errors can mean not having enough boxes to fulfill an order, products going to waste, or even the wrong products going out. The Stevens Packaging module will allow you to save time and eliminate the risk of these errors thanks to its automatic calculation of requirements. Whatever the number of final products you require in a given sales order, the Stevens System will automatically calculate the total stock or ingredients needed.

Flexible and Adaptable:

At Stevens, we understand the need for flexibility across operational processes. This is why we have designed our packaging module with that need in mind. With easily customisable elements, you and your operators can set this module up to suit your business requirements, with the freedom to adapt on the go. One such tool for this is the ‘on-the-fly’ expiry adjustments, which can be made during the weighing and packaging process, this allows you to ensure that products are marked correctly as and when needed. Additionally, configurable buttons on the terminal itself means you can tailor it to perform the processes and access the information you need, when you need it.

Full Traceability Throughout:

As a modular component in our wider Dynamic Traceability System, Stevens Packaging is designed to provide you and your business with full traceability throughout the packaging process. Manage and confirm which batches are going into products, and which items are being used to package them. This helps provide you and your business with insight into your final product’s journey through your operations. With this insight, you can ensure transparency across supply chains, and more importantly, maintain your customers’ trust.

Overall, the Stevens Packaging Module is the ideal solution for managing your final production processes. It allows you to schedule your processes with ease and remains flexible to change according to your needs. Further to this, it minimises the risk of error across the management of your stock items, and the preparation of your packaged product. All this, while providing traceability through the latter stages of production, providing the insight to enable transparency across your products consumers and suppliers.

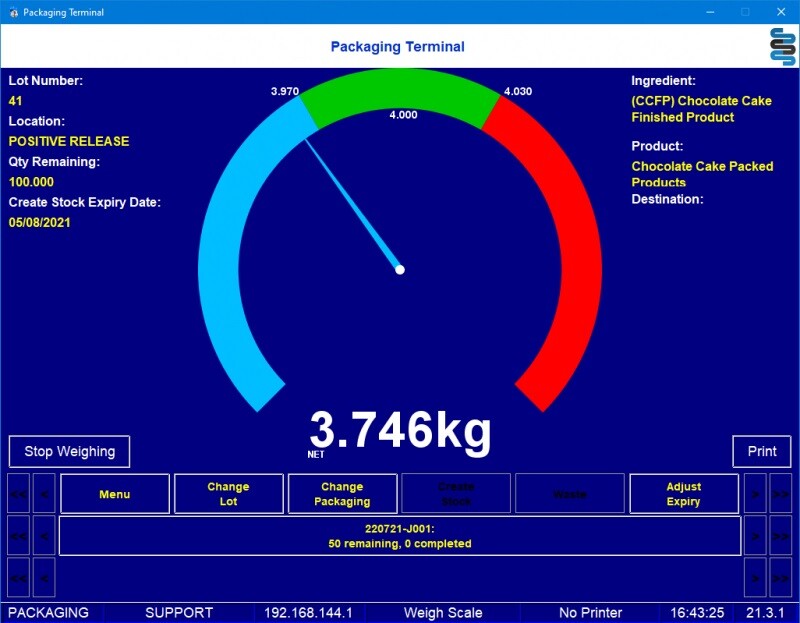

Picture 3 Caption:

Adjust expiry dates on the fly.

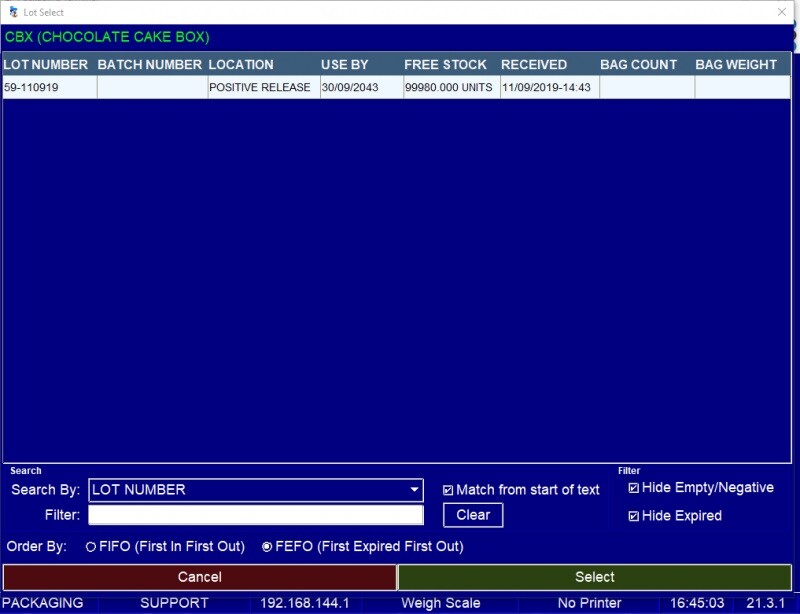

Picture 4 Caption:

Maintain traceability throughout your process.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.