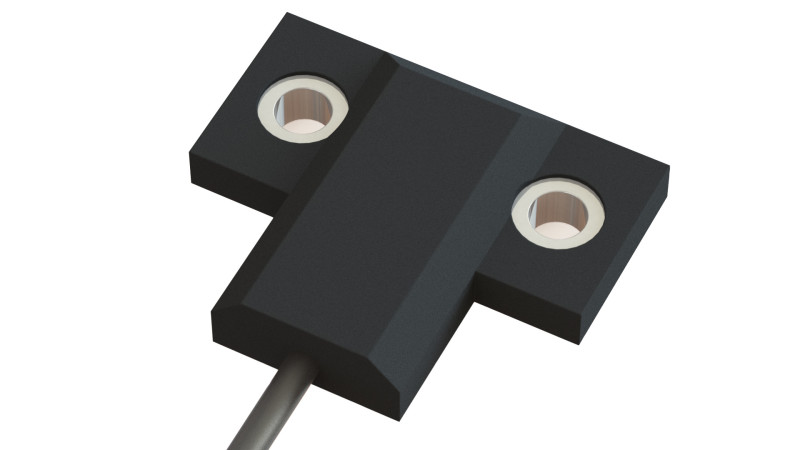

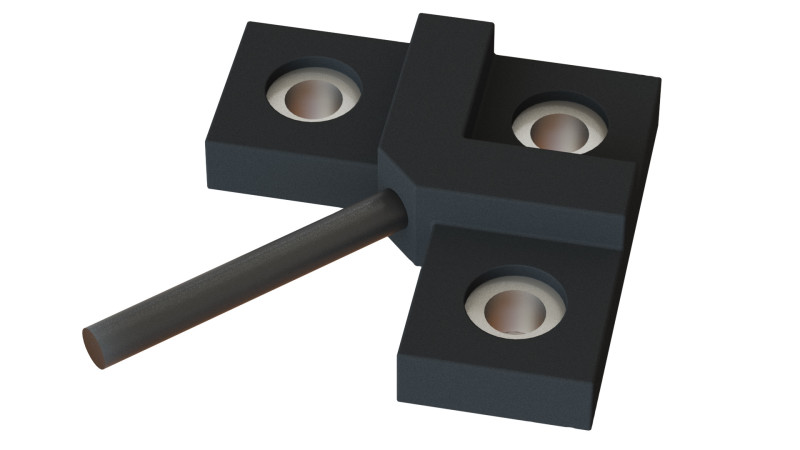

Datum Electronics (United Kingdom) - Bolt-On Strain Gauge Sensors measure changes in the stress levels of vessel or structure support, producing an electrical output proportional to the changes in weight. Designed to easily fit numerous applications in any harsh environment, they eliminate the need for complicated and costly installation works and provide accurate and reliable results for many years.

Growing Importance of Bolt-On Sensors:

Current stringent legislation and a rise in demand for high-performance vehicles in many industries, including automotive, agricultural, marine, mining to name just a few, and compliance with safety standards urges millions of manufacturers to look for accurate and reliable weighing data.

For over 25 years Datum Electronics have been designing and making Strain Gauge based Load Monitoring sensors and instrumentation with the ability to supply sensor designs to meet all customer requirements. Working in partnership with established manufacturers across many industries, we produce at our headquarters thousands of bolt-on sensors every year.

Our Bolt-On Strain Gauge Sensors are robust, dust & water resistant, suitable for the harshest of environments and can endure high-stress levels. Unlike other strain measurement, load and weighing systems, they are easy to install without soldering or wiring and designed to fit a wide range of applications.

On-Board Heavy Vehicle Weighing Systems:

Overweight trucks are a hazard and affect road as well as vehicle safety. To prevent road incidents in the past, trucks used to be weighted on static scales. For that reason, they had to stop and wait to be weighted sometimes for over 30 minutes. Recent European regulations have addressed this issue, making on-board weigh (or weigh in motion) systems a real priority for heavy vehicle manufacturers.

Datum Bolt-On sensors are compact in size, can be temperature compensated (optionally) and designed to be easily installed. These strain gauge bolt-on sensors are usually mounted on each group of a vehicle’s bridge or an axle, acting as a weighing scales and providing a reliable and accurate data to a vehicle’s system as live data available continuously.

Silo Strain Measurement Weighing:

A conventional weighing system for a silo, hopper or a tank can be quite an expensive solution and is not for everybody. A simple bolt-on sensor, on the other hand, is cost-effective and causes a minimum disruption and down time.

Our Series 460 Strain Gauge bolt-on sensors are bolted to a silo’s leg or skirt with a little change to its structure and therefore its integrity. When supports are deformed due to load, the strains are conveyed to the strain gauges, giving an output signal proportional to the load that is transmitted to a customer’s system or interface of choice.

Vessel Weighing:

Prompted by recent EU legislation, vessel condition monitoring is becoming increasingly critical in the maritime industry. For example, to enhance safety and increase operational efficiency of ships carrying cargo, IMO highly recommends fitting hull stress monitoring systems on vessels of 20,000 dwt and above.

Strain Gauge Bolt-On sensors measure hull loading levels that can show early signs of damage or degradation, significantly reducing the cost of repair and maintenance. This simple, easy to fit hull stress monitoring sensor is designed to enable vessel operators with real-time information on the stress the ship’s hull experiences during loading and unloading operations.

Weighing Applications:

Increasing safety and avoiding unscheduled downtime are crucial issues in today’s competitive mining industry. One of the critical areas of focus is based on the reliability of conveying systems. These conveyor and truck/trolley systems are usually subjected to medium to extreme vibration and stress levels. Having a dedicated condition monitoring system can give confidence that heavy rotating machinery is operating correctly at various speeds and loads without malfunctions.

Our Bolt-On sensors can be placed along the belt conveyor system and on trolley systems to deliver continuous real-time data to mining operations personnel to reduce the impact on product and maintenance costs.

Underwater Strain Measurement Applications:

Different offshore structures (pipelines, dams, bridges, tunnels) and offshore energy-related structures (wind farms and other energy harvesting constructions) can suffer from scouring and cracks that can compromise the safety of the structure. As inspection, maintenance and repairs of underwater structures are very costly, offshore structural monitoring has become an essential part of a variety of underwater applications to prevent avoidable failures.

Our bolt-on strain measurement sensors can be installed to the structures underwater and don’t require any welding or drilling. These sensors offer high strain resolutions, providing real-time information, and can survive high sea water pressure, presenting an excellent durable and reliable solution for underwater conditions.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.