Bizerba (Germany) - With BRAIN2 Formulation, Bizerba releases a new piece of industry software for manual formulation and dosing. The program ensures better safety, as it guides the operator carefully through the process and it enables complete batch traceability. Formulation also manages the master data centrally and tracks changes via audit trail. The software seamlessly dovetails into the BRAIN2 software platform and can easily be integrated into existing Bizerba systems.

It is essential in both the food industry and in the chemical industry to measure out ingredients accurately down to the milligram. Just a single overdosed ingredient is enough to render the product worthless. The BRAIN2 Formulation software by Bizerba increases process safety as it guides the operator carefully through the procedure and verifies the material number for each order item. It also displays the mandatory action symbols and hazard symbols so that the operator is always aware of the current stage in the process and appropriately protected. The software manages all master data centrally, including material information, basic formulas and instructions. This enables the precise control of production processes, starting with the individual formulation workstation right through to comprehensive client server solutions. Higher-ranking ERP systems are able to exchange the stored orders, formulations and results data by means of a file interface. The software also supports those responsible for production in tracing entire batches.

Excellent flexibility and safety:

In order to make production as flexible as possible, customer-specific settings can be applied on each workstation. For example user accounts, password guidelines and rights can be defined freely and depending on the safety requirements. If required, BRAIN2 Formulation also creates cyclical backups of all important production information. On top of that, the software offers an audit trail function which enables all production details to be traced. It records who has made a change, when and at which terminal, so that the individual stages can easily be traced in the event of a complaint.

Touch Client for easy operation directly on screen:

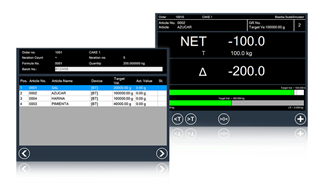

In conjunction with the Bizerba Touch Client application customers have the option to present more information and formulation stages in detail on PC terminals, such as the iS65 or iS70. The Touch Client functions as a man-machine interface in this case, which guides the user through the formula step by step. The touch screen shows safety instructions using hazard symbols. To use the Touch Client, a terminal with a load receptor or the NTscale software is needed additionally.

This website uses cookies. By browsing our website you accept the use of cookies. For more information read our Terms of Use.

Always the right formula: BRAIN2 Formulation software for manual formulation and dosing from Bizerba

- By Bizerba

- Posted on May 19, 2015

For more information about this article from Bizerba click here.

Interesting Links:

List all your Scales and other Weighing Products (new and used) on our Marketplace !

Visit AutomationInside.com for Automation and Technology Related News!

Are you interested to include your Link here, visible on all WeighingReview.com articles and marketplace product pages? Contact us

List all your Scales and other Weighing Products (new and used) on our Marketplace !

Visit AutomationInside.com for Automation and Technology Related News!

Are you interested to include your Link here, visible on all WeighingReview.com articles and marketplace product pages? Contact us

© Bizerba / International Weighing Review

Previous article

HBM's New HLC legal-for-trade Load Cell for the small measuring range of 110 kg

Next article

Flexible Weighing System from Siemens gets the rocks rolling

Popular News

Weighing Review Newsletter

Popular Tags

Login

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.