Load Cell Central (United States) - Load pins (also called clevis load cells or pin load cells) are designed for applications where the amount of force exerted on a pinned joint must be measured. Applications can be found across many industries, including aerospace, automotive, manufacturing, and marine, to name a few. Examples of common pin load cell applications would be overload prevention in crane and hoist systems, measuring piston pressure, mooring line testing, and bridge support cable monitoring. Pin load cells have many advantages over other load sensors, the main advantage being that they do not typically require any change to the structure of the machine or device being monitored.

General Load Pin Description:

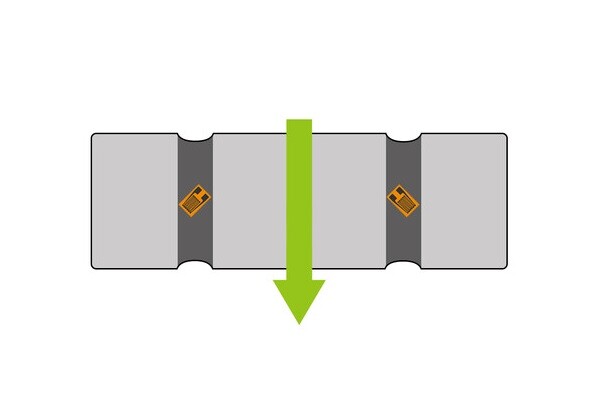

Load pins are rod-shaped load cells that can replace normal shafts or pins in machinery such as shackles, sheaves, bearing blocks, pivots, pulleys, and much more. Fitted with internally mounted strain gauges, load pins are able to measure shear strain and produce an electrical signal proportional to the measured load.

Advantages of Load Pins:

As previously stated, the main advantage of a pin load cell is that they integrate seamlessly into most applications. Since pin load cells replace weight-bearing pins that would already exist in the application, installing a load pin is, structurally speaking, little more than swapping one part out for another.

Another benefit of using clevis pin load cells is that they affect no change on overhead space. Any other type of load cell will reduce, often substantially, the functional workspace of the crane/hoist/pulley.

Pin load cells come in a multitude of shapes, sizes, and capacities and can therefore replace almost any pin. Customization also increases the versatility of this load cell and is a commonly used option for manufacturers. Load Cell Central specializes in helping you obtain the best possible load pin for your unique application.

Safety:

Without the need to add, remove, or splice segments of cable to integrate into an application, using load pins circumvents potential safety issues that can arise from faulty installation of load monitoring equipment.

Clevis pin load cells are very reliable and are available in extremely high capacities. This is essential for monitoring weight and strain in order to prevent overload, even in applications involving hundreds of thousands of pounds.

Environmental Protection:

Corrosion, rust, and other damage caused by moisture, debris, dust, and other environmental factors are a common problem with load cells used in an industrial setting. Stainless steel construction plus internally mounted strain gauges mean that Load Cell Central’s pin load cells can be used in almost any environment with little to no damage. With submersible and wireless options available, possible applications for these load cells are endless.

By Dara Trent, Technical Content Director.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.