Scanvaegt Nordic A/S (Denmark) - Damifo A/S works with the recycling of building materials and endeavours to ensure that as much construction waste as possible is recycled into something useful rather than ending up in a landfill.

Damifo / Dansk Miljøforbedring, which has branches at three locations in Denmark, receives materials from the construction industry for recycling and ensures that they are handled efficiently and in an environmentally sound manner. These materials include asphalt, mixed waste, concrete, bio-ash/incineration slag, aerated concrete and gypsum, soil, bricks and various wood materials. After sorting and processing, the materials are sold as crushed asphalt, recycled base, crushed concrete, recycled ballast, topsoil, wood chips, etc.

Upon receipt, all materials are weighed on a weighbridge and registered with weight, type/fraction, supplier and haulier/carrier, and agreement no. This information is to be used for invoicing, inventory management and resale, as well as for reporting to the Danish Environmental Protection Agency.

Efficient registration process:

It can be very busy with up to 160 cars a day being weighed in and out, so weighing and registration must be done efficiently to avoid waiting time and long queues.

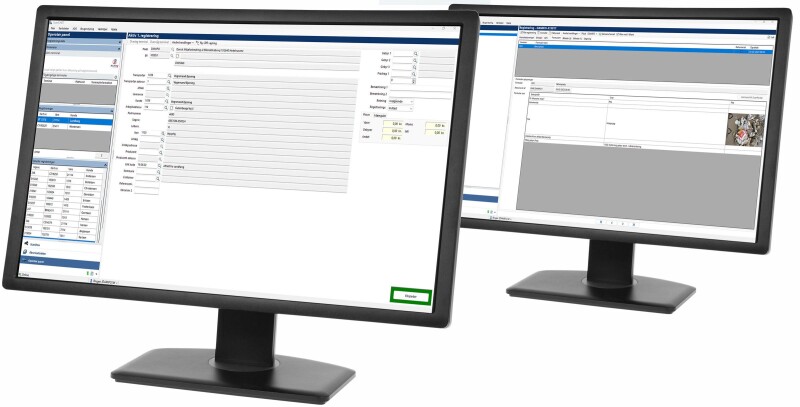

Damifo handles this task today with the ScanX.NET software solution, which they started using in the spring of 2021. The solution consists of the basic module and several add-on modules for managing multiple geographical branches, import/export of data, e-mail reports, camera surveillance and photo documentation. The scalable software system can be expanded with more modules as needed.

"The system is easy to work with, and carrying out the registrations as become quicker. And we now have greater data certainty for correct registrations." - Kenneth Frederiksen, Project manager Damifo A/S.

Easier, faster and better overview:

Project Manager Kenneth Frederiksen has been in charge of implementing the ScanX.NET solution and is responsible for ensuring that the daily operations run optimally and are constantly improved. He is delighted with the system and has noticed several improvements. He explains: "I generally find the system easy to work with, and carrying out the registrations as become quicker. The whole soil programme/agreement programme has made the work much more manageable than what we had before. And we now have greater data certainty for correct registrations".

He continues: "I am particularly pleased with the management of the agreement numbers – it has given us complete overview and control. I am now working on the delivery programme, which includes different materials and quantities. Here I can create different delivery types under the same agreement number. For example, if the soil comes from the same place or a construction site contains both wood and waste, then it can be entered under the same agreement number. When I need to gain an overview of what the vehicle has brought with it, I can extract this based on the agreement number".

Management of multiple geographical branches:

With the ScanX.NET module Facility Control, Damifo can manage its other branches and collect data and support them. Kenneth says: "Everything runs on the same SQL, so all data is transferred to us. And our department in Rødby can call us here in Hedehusene, where we can support them directly and, for example, guide the drivers to the right weighbridge terminal and explain how the process works. We can also "remotely operate" the terminal and click in the right places for the driver".

Digitalisation prevents errors and saves time:

Damifo also uses the LPR module, which uses a number plate scanner to automatically identify trucks as they weigh in and out on the weighbridge. This has several advantages, Kenneth explains: "The scanning is done quickly, so the driver saves time. We also avoid having to deal with worn out plastic/ID cards that cannot be read by the weighing terminal and therefore display errors".

Scaling up the system continues:

Kenneth is constantly looking to improve operations and utilise the ScanX.NET solution to ensure correct data and save working time. Damifo has recently implemented two more ScanX.NET modules - ADS/Waste Data System and Delivery Inspection for reception control.

Kenneth explains the reason for this: "We have to report the many fractions to the authorities, and here we have chosen to use the ADS/Waste Data System. It records the type of waste on both incoming and outgoing vehicles, which is stored in the database, and organises the reporting to the Danish Environmental Protection Agency.

With the second module - Delivery Inspection - Damifo is able to easily carry out mandatory reception controls by weighing waste fractions, recording discrepancies on the declared waste fractions with image documentation, and weighing the vehicle.

"With the Facility Control module, we can support our other branches. Our department in Rødby can call us here in Hedehusene, where vi can guide the drivers to the right weighbridge terminal and explain how the process works. We can also "remotely operate" the terminal and click in the right places for the driver." - Kenneth Frederiksen, Project manager Damifo A/S.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.