As a company that manufactures and services onboard weighing solutions and payload management equipment worldwide, VEI’s solutions can be found on a diverse range of industrial vehicles, including excavators, wheeled loaders, rigid dump trucks, forklift trucks, articulated dump trucks, and underground load haul dumpers (LHDs).

The company’s new generation of devices feature a bright colour display that it claims is unequalled elsewhere in the industry. Visibility in direct sunlight is assured. The VEI software interface also makes these devices very easy to use, with wireless connection availability making weighing data available anywhere in real time. With a worldwide trained network of companies, VEI promises a high level of service and technical backup. Its systems can be linked to third-party dispatch systems with ready communication protocols in place.

The new technology allows the VEI onboard weighing device to be connected to the vehicle CANbus J1939, making possible one sole display for the payload monitoring activity and vital machine information. All data can be linked wirelessly to a remote location.

Payload monitoring saves money:

Haulage cost will be a headache for many mining companies when they run a fleet of vehicles that is unable to give them the maximum transported payload. Driving mining equipment is very expensive too, so it is extremely important to know every single tonne moved across the mine, in order to understand the driving cost of each tonne and the matching capability of the haulage trucks and loading excavator. A four-pass load might be less expensive, operationally, than a seven-pass load, meaning a different machine will therefore be needed.

With its onboard weighing solutions and payload monitoring, VEI is able to meet the need to drive down haulage costs with a range of high-tech devices mounted onboard the loader, haulage truck or excavator that are capable of delivering the tonnage loaded or hauled. Payload monitoring is delivered by easy-to-use software applications wirelessly linked to the onboard device or by connecting the VEI device with any make of onboard fleet-dispatching system.

Installations conducted worldwide, across Russia, India, Colombia, South Africa and Brazil for example, have left customers highly satisfied with their newfound ability to control loads moved and therefore drive down costs per tonne via an increase in production of 15% – purely by payload monitoring. They can therefore more efficiently plan equipment size, quantity and availability, as well as improve maintenance procedures and operator training. Overloads have been reduced to zero, resulting in more efficient equipment parking.

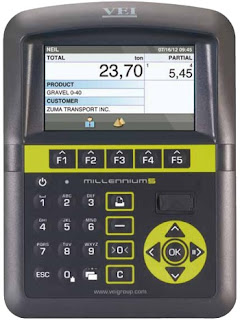

VEI’s Millennium5 and HelperX new generation takes into consideration in-cabin space, ergonomics, visibility, ease of use and connectivity, while reducing the amount of componentry. In-cab space is optimised by the innovative design and applied electronics, which have permitted the building of a novel CPU controller board to work with any other peripheral board.

The casing design development has gone through stages of prototyping and test application on the machines, in order to validate project aims. The upper casing surrounding the display has been created to protect the display while giving a high degree of protection against bright lights.

The optional printer casing has been designed to be incorporated on the bottom of the device, requiring minimum space and developing the whole unit into the vertical axis, which still allows perfect visibility from the machine when applied to the cabin pillar, enabling the ease of maneuvering to remain untouched.

User-friendly devices:

The components of the display have been chosen from the many available on the market. The selected screen provides the best visibility in bright sunlight even when compared with an iPhone.

VEI’s extensive technology expertise has enabled the development of a powerful CPU to drive the graphics on the display, keeping costs down for the introduction of the device into the market for basic weighing system requirements. Graphics have been studied to the smallest detail to deliver a user-friendly interface, which has been confirmed in the first four months of its introduction on the market – both customers and operators are attracted by the ‘cool’ appearance and the extreme ease of use due to the graphics and full text help of the device navigation.

Particularly important has been the close relationship between the R&D department and field users. The software structure enables OEMs to have their own software customised for the typical application where the device is going to be used, and the J1939 CANbus extends possibilities even further when working with manufacturers on the design of a single unit governing the entire machine.

Connectivity is an important aspect of today’s working environment, and VEI’s new-generation devices have it all: short-range RF, WiFi and GPRS. Data can be linked to a remote location, keeping the machine working in the field while it remains continually connected to the central operational site for two-way communication. This reduces the time delay between loading and invoicing or production, enabling instant decision making and even allowing the machine to load for authorised customers only.

The device incorporates all necessary components, without the need for any external black boxes, which are often damaged by harsh working and climate conditions. This is a further benefit for industrial vehicle manufacturers searching for field-proven solutions.

Source Link

Other Articles from Veigroup (Italy)

© Veigroup (Italy) / International Weighing Review

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.