[Article]: How Load Cells Work: From Strain Gauges to Digital Signals

Load cells are the heart of any weighing system — responsible for converting mechanical force into measurable data. But how do they really work? This complete guide explains everything from strain gauge technology to signal conversion, helping you better understand, specify, and troubleshoot load cells in your applications.

What Is a Load Cell?

A load cell is a type of transducer that converts applied force, typically weight, into an electrical signal. This signal can be processed and displayed by a weighing indicator or transmitted to control systems. Load cells are essential in industrial weighing, automation, process control, and force measurement tasks across multiple industries — from logistics to pharmaceuticals.

Types of Load Cells

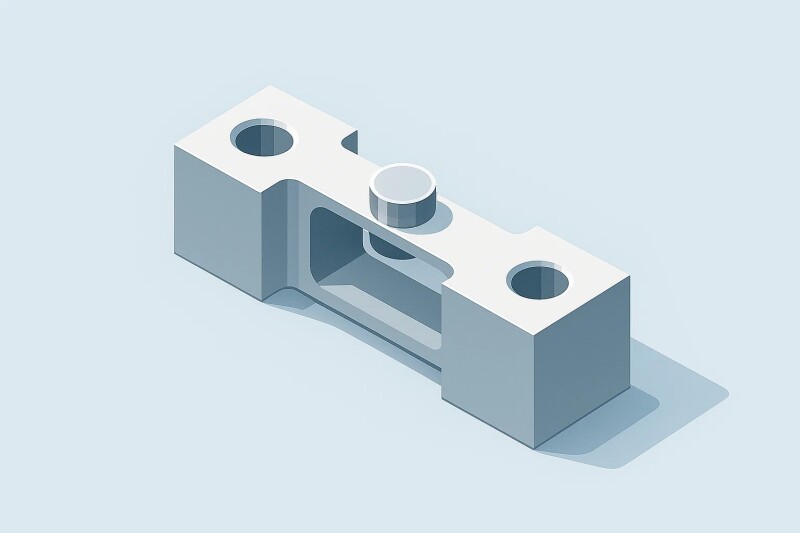

- Strain Gauge Load Cells: These are the most widely used type. They consist of foil strain gauges bonded to a metal element (usually aluminum or stainless steel). When force is applied, the element deforms slightly, and the strain gauges measure the resulting change in electrical resistance, which is proportional to the applied load.

- Hydraulic Load Cells: These use a fluid-filled chamber. When a load is applied, it compresses the fluid, generating pressure that is measured by a pressure sensor. They are ideal for hazardous or explosive environments where electrical components could pose ignition risks.

- Pneumatic Load Cells: Similar to hydraulic types, but use compressed air. They are commonly used in cleanroom applications such as semiconductor and pharmaceutical industries, where contamination must be avoided.

- Capacitive Load Cells: Use changes in capacitance between plates as the sensing method. They offer high sensitivity but are more susceptible to environmental interference.

Signal Processing

The raw output from a strain gauge load cell is a very small analog voltage (typically in millivolts). This signal passes through a series of stages:

- Amplification: The signal is amplified by an analog amplifier to make it suitable for processing.

- Filtering: Electrical noise is removed through low-pass filters to ensure signal stability and accuracy.

- Analog-to-Digital Conversion (ADC): The cleaned signal is digitized for use by a weighing indicator, PLC, or digital controller.

- Linearization and Compensation: Advanced electronics correct for temperature drift, non-linearity, and hysteresis to ensure consistent measurements.

Common Applications

- Platform scales and bench scales in logistics and retail environments

- Tank and silo weighing for batch processing in chemical and food industries

- Industrial automation with embedded load cells in robotic arms or production lines

- Vehicle weighing systems, such as weighbridges or axle scales

Conclusion

Understanding how load cells work — from their internal mechanics to signal processing — is crucial when designing, installing, or troubleshooting any weighing system. Selecting the right type of load cell for your environment and application can dramatically improve measurement accuracy, safety, and operational efficiency. Whether you're dealing with analog strain gauges or digital load cells, knowing how to interpret and manage their signals is key to reliable performance.

Looking for the Right Load Cell for Your Project?

At Weighing Review you will find articles and other contents about all type of scales and other weighing solutions such as technical articles, videos, case studies and guides. You can also search the Suppliers Directory and Marketplace to find the best supplier and product for your weighing needs.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.