Following this philosophy, HASLER International just finished a line of DSB measuring and injection equipment, called “fluffs”, consisting of a mixture of paper, cardboard and shredded plastic. The purpose of this installation is to use more alternative fuel to reduce energy and production costs. With this objective to reach 5 t/h on machine release, the need for regular flow measuring is our main goal.

The purpose of this installation is to use more alternative fuel to reduce energy and production costs. With this objective to reach 5 t/h on machine release, the need for regular flow measuring is our main goal.

For many years, HASLER has provided its customers with measuring and weighing equipment to meet the many needs of the cement process industry. Within this framework, HASLER International and its clients have carried out research for different solutions for reliable installations.

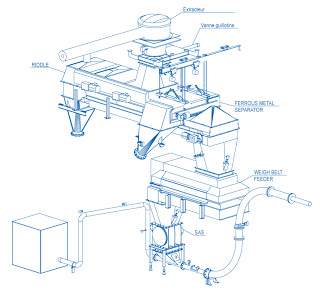

The GRAVIT light was the choice approved by both parties for its many positive features, including its light band, digital weighing, input weighing, waterproof channel and extended range. These characteristics correspond in all respects with the specifications of the product such as its volatile matter, low density, etc. The belt feeder is equipped with a SCMII provided in a complete switch cabinet.

The GRAVIT also comes equipped with an inflatable conveyor under the belt feeder which consists of a blower, a speed box and an alveolar airlock, allowing the product to be directly injected to the kiln nozzle (located about 30 meters from the measurement installation).

The quality of the product received by the client – the "fluff", can vary and in order to ensure proper operation of the entire system, it is advised to add a star screen and a ferrous metal separator upstream to the weigh belt feeder. The objective of these two devices is to protect the alveolar airlock avoiding metal and pieces of large dimensions. Machinery operators have shown their trust in HASLER equipment in many different areas of the factory because of the high level of precision reached with each system.

There is also less wear and tear with the GRAVIT compared to other weighing equipment used in the past due to fewer replacements of parts and less maintenance requirements.

Source Link

Other Articles from HASLER International (France)

© HASLER International (France) / International Weighing Review

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.