Yamato Scale Co., Ltd. (Japan) - Multihead weighers are an essential part of many production lines, enabling you to weigh and sort a wide variety of raw materials to meet the required specifications of your end products.

Due to the integral role of the multihead weigher, you must find the right one for your plant. This means weighing up multiple factors to identify a solution that works for you and your products.

If you find a weigher that suits your plant, you will unlock huge benefits: including increased productivity, higher quality output and faster processing speeds across your production.

This article explores what you should look for when choosing a multihead weigher to ensure you make the right choice.

- Materials

- Accuracy

- Productivity

- Cleaning and maintenance

- Energy consumption

- Alignment to processes

- Data analysis

Materials:

When selecting any equipment for your plant, the first thing to consider is whether it is compatible with the raw materials or ingredients that you will process on your line. Different materials have unique characteristics that can pose challenges throughout production, so you need to ensure you have the appropriate solutions in your line to make the job smoother and raise the quality. This applies to your choice of multihead weigher.

Start by listing out any materials that will be processed through the weigher. Depending on the set up of your plant, this could be one specific type of material, or it could include a variety of materials across projects.

Once you have identified your materials, ask yourself what requirements they have. For example, if you work with sticky or liquid materials, such as fresh produce or confectionary, you would not need features on your multihead weigher required for frozen food or hardware.

Examples of features that may be included to handle problematic materials include:

- Dimple-plated buckets for sticky materials to prevent them from sticking to the machine

- Plain buckets for dry materials to enable them to move across the line easily

- High IP ratings and waterproof specifications (such as stainless steel) for liquid materials

- Varying bucket shapes with larger radius corners making cleaning easier for messy materials

- Reduced feeder amplitude and smaller drops for fragile material handling

Some providers may be able to adapt their models to add in these features and tailor them to your production line needs.

By identifying multihead weighers that are fully compatible with your materials, you will speed up the production process by allowing items to move along your lines smoothly. It will also increase the quality of your output and prevent unplanned downtime through equipment errors or materials getting stuck along the line.

Accuracy:

When weighing your materials, it is essential to be accurate. This includes weighing your raw ingredients, ensuring you have exactly the right amount for processing and reducing giveaway, and that your final product meets the packing and labelling specifications.

Accuracy is also essential to ensure consistency across all output while reducing costs by enabling you to get the most from your materials and reducing the risk of waste or having to reprocess faulty products.

Due to this, any multihead weigher you purchase must perform. Many factors contribute to accuracy. On top of ensuring the machine is compatible with your products, you will also want a robust feeding system, high-frequency load cells and reliability. This will enable your weigher to consistently do its job, leaving you with perfectly sorted materials with minimal need for intervention.

Productivity:

Every manufacturer wants to maximise its productivity. Enhanced productivity usually means reduced costs, limited unplanned downtime and faster turnaround, enabling you to meet higher levels of demand.

Alongside having reliable machines, speed and volume will impact productivity the most. Essentially, you want to process as much material as possible, as fast as possible, without compromising accuracy or quality.

When sourcing a new multihead weigher, you need to compare weighs per minute, as this will determine how quickly you can weigh materials. Load cell frequency may also play a part, as higher frequencies mean a shorter settle time, allowing you to move materials faster.

Another factor to consider will be how large a volume the system can withstand at one time. The weighing range will tell you this – however, the number of weigh heads can also help to increase the volume that can be handled and sorted, depending on your production needs.

Cleaning and maintenance:

To maximise productivity and for ease of use, it is imperative that your machines can be quickly cleaned and maintained.

A faster cleaning ability enables you to turn around lines quicker while avoiding cross-contamination when reloading your weigher with a new batch of materials. In the case of sticky or liquid materials, like fresh produce, being able to clean your machine easily is crucial to prevent build-up in your buckets or prevent other products from being damaged. Hygiene is also critical to your compliance.

Maintenance is essential, given that a badly calibrated or poorly maintained machine can compromise accuracy and productivity, resulting in unwanted downtime, disruption and repair costs if the problem is allowed to manifest. By having a rigorous maintenance programme, this will allow issues to be resolved quickly, so that the line can be up and running with minimal lost time.

When seeking a multihead weigher that promotes ease of maintenance and cleaning, you should look for features like IP rating (which reflect how waterproof a machine is, impacting how you clean it), bucket shape (larger radius corners tend to be easier to clean) and removable parts (so you can clean those parts thoroughly, or take them off in the case of maintenance).

It’s also worth checking with your system manufacturer to see if they offer maintenance plan as well as swift access to spare parts. This enables you to stay on top of maintenance and act swiftly when there is a fault while ensuring a long-lasting and efficient repair.

Energy consumption:

Environmental impact and green targets are moving up the agenda for manufacturers, in line with the UK government’s net-zero goals. With this in mind, any machine you purchase must start to play into your business’ mission to improve eco-friendliness, so you need to find options that will reduce your carbon footprint.

While all production lines do need power to run, it is possible to find multihead weighers with reduced power consumption that limits the amount of energy you are using during your production process. This can support your other activities to minimise your impact on the environment.

The accuracy of your multihead weigher will also help to improve these credentials as with accurate systems comes the ability to reduce waste and improve productivity, allowing you to reduce energy consumption by not having to reprocess lines or throw away materials.

Alignment to processes:

If you are purchasing a multihead weigher to fit into your existing lines, you need to ensure that it is compatible with the equipment and processes you already have in place. For example, elements like discharge points can affect product flow through your line, so your chosen system must allow your products to flow in the way you would like and integrate easily to the equipment that may form part of that line (such as conveyor belts).

Many multihead weighers are pre-programmable, allowing you to set tasks and input your parameters so it processes materials in line with your specifications. This is an important feature as it allows you to input your existing requirements – such as the guidelines agreed with your customer or processes already created in your plant – and continue to adhere to them. It will facilitate consistent results, through repeatable programmes, automating your processing and reducing the need for manual intervention.

Speak to the supplier of any weigher you are considering and discuss the in-house protocols it needs to connect to. They should be able to talk you through the compatibility of the system – and, in some cases, even provide a bespoke solution for your plant.

Data analysis:

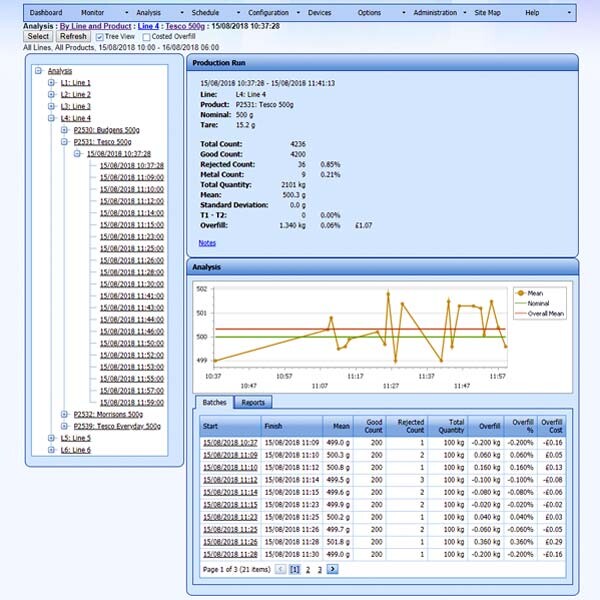

When you invest in any machinery, you want to ensure you are getting the best possible performance. Selecting a solution that contains data analysis will enable you to review performance regularly and ensure your multihead weighers and lines are fulfilling its purpose.

With data analysis, you will optimise your output by ensuring that every function is carried out correctly and resolving any issues ahead of time. This means you can guarantee your production line works to maximum capacity, driving the results you want through high-quality end products. It will also assist your traceability and auditing.

Conclusion:

As with any type of machinery that forms part of your production line, you need to ensure that your multihead weigher offers you high performance and great results.

Finding the best solution means shopping around and comparing models based on accuracy, compatibility, productivity and total cost of ownership as well as other factors that may be a priority in your plant. Once you do find that suitable weigher, it is a case of integrating it into your production lines and then you will obtain your return on investment through improved productivity and enhanced quality.

Yamato offers world-leading multihead weighers, with a plethora of models that boast outstanding performance, affordable prices and flexibility to your production needs. We also provide support for installation, maintenance and commissioning.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.